500kg 48V Electrified Wheelbarrow 360°rotating Hydraulic Tipping Mini Dumper

View MoreElectric Mini Dumper Manufacturers

Product Customization Services

We offer comprehensive customization services, including product color, logo, nameplate, and instruction manual, to meet your specific needs.

Product Q&A

-

Q: HOW LONG CAN I GET THE FEEDBACKS AFTER WE SENT THE INQUIRY?

We will reply to you within 12 hours of the working day.

-

Q: ARE YOU A DIRECT MANUFACTURER OR TRADING COMPANY?

We are a company that specializes in producing mini dumpers in our factory. We create and sell all by ourselves.

-

Q: WHAT PRODUCTS CAN YOU OFFER?

We mainly produce mini dumpers and related accessories.

-

Q: WHAT APPLICATIONS DO YOUR PRODUCTS RELATE TO?

Our products have many uses, mainly involving construction, farms, landscaping, mining, and other industries.

-

Q: CAN YOU DO CUSTOMIZED PRODUCTS?

Yes, we can develop and produce products based on the drawings or samples provided by the customer.

-

Electric Mini Dumper: Why Compact Electric Haulers Are Shaping Small-Scale Construction and Landscaping Electric mini dumpers have quietly moved from ...

READ MORE -

What Buyers Should Know Before Working With an Electric Skid Steer Factory Electric skid steers have moved well beyond a curiosity for early adopters:...

READ MORE -

Choosing and Working with a Motor Wheelbarrow Manufacturer: A Practical Guide for Contractors and Buyers If you move soil, rubble, or materials on a j...

READ MORE -

How Electric Mini Dumper Fits into Modern Jobsite Workflows Electric mini dumpers are changing how small and medium jobs manage material movement. Com...

READ MORE -

Electric Mini Dumper has become a go-to tool on tight, busy sites where moving material quickly matters but space and noise are a problem. Walk onto a...

READ MORE

Can a Battery Powered Mini Dumper Handle Steep Inclines Effectively?

In the field of modern engineering, small dump trucks are undergoing a power revolution. The high pollution, high noise and maintenance costs of traditional fuel equipment have forced the industry to look for alternatives, and battery-driven technology has become the core of this change with its clean and efficient characteristics. However, there has always been a controversial focus in the industry: Can battery powered mini dumper remain efficient and reliable in extreme working conditions such as steep slopes?

1. Technical challenges of steep slope conditions

In construction, mining or mountain operations, steep slope transportation places strict requirements on equipment:

Power system: It is necessary to provide high torque at low speed to overcome gravity and friction resistance;

Energy management: Continuous high-load operation may cause battery overheating or a sudden drop in battery life;

Stability: The body design needs to balance the load and center of gravity distribution to prevent the risk of rollover;

Safety: The braking system needs to deal with the thermal attenuation problem of frequent start-stop and long-distance downhill.

Traditional fuel equipment relies on the instantaneous explosive power of the internal combustion engine, but can battery-driven technology break through these limitations?

2. Breakthrough of battery-driven technology

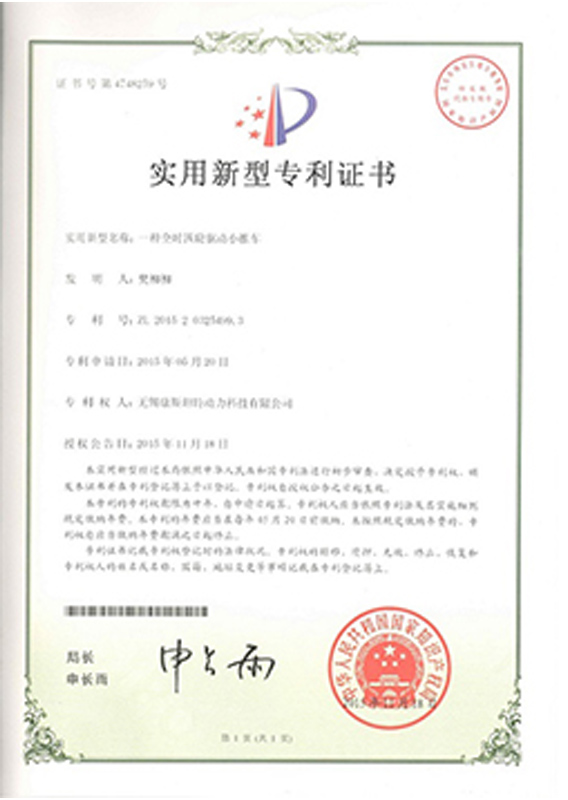

Take WUXI KONSTANT POWER TECH CO., LTD's innovative products as an example. Its battery-driven mini dump truck has achieved a disruptive breakthrough in steep slope performance through three core technologies:

1. Permanent magnet synchronous motor and intelligent electronic control system

Instantaneous torque output: The motor can provide 100% peak torque at 0 speed, and the climbing ability is more than 30° (traditional fuel vehicles are about 25°);

Adaptive power distribution: Real-time monitoring of slope, load and battery status through the CAN bus, dynamic adjustment of motor power to avoid energy waste or overload;

Regenerative braking technology: When going downhill, the kinetic energy is recovered and converted into electrical energy, extending the endurance by 20%, while reducing brake pad wear.

2. High energy density battery pack and thermal management system

Lithium iron phosphate battery: uses 280Wh/kg high energy density battery cells, which can maintain stable performance in -20℃ to 50℃ environment;

Liquid cooling + air cooling dual heat dissipation: The battery temperature difference is controlled at ±2℃ through the intelligent temperature control system to avoid high temperature attenuation or low temperature capacity loss;

Modular design: supports rapid replacement of battery packs to achieve continuous operation capability of "charging for 5 minutes and working for 2 hours".

3. Mechanical structure and material innovation

Low center of gravity trapezoidal frame: uses high-strength aluminum alloy material, reduces the dead weight by 30% and increases torsional rigidity by 40%;

All-terrain suspension system: four-wheel independent suspension with anti-skid tracks, and the adhesion on slippery steep slopes is increased by 50%;

Overload protection device: when the load exceeds the rated value by 15%, the system automatically limits the motor output to prevent mechanical damage.

3. Industry Trends and Future Outlook

According to the "2025 Global Construction Machinery Electrification White Paper", the market share of battery-driven mini dump trucks will jump from 18% in 2023 to 45% in 2030. This transformation is not only driven by environmental protection policies, but also benefits from the full life cycle cost advantages brought by technological breakthroughs:

Energy cost: The hourly electricity consumption cost of electric equipment is only 1/3 of that of fuel vehicles;

Attendance rate: Modular design reduces the maintenance response time to within 2 hours;

Residual value rate: The equipment value retention rate during the battery life cycle (about 5,000 cycles) is 35% higher than that of fuel vehicles.

Through the collaborative innovation of permanent magnet motors, intelligent electronic controls and battery thermal management technologies, battery-driven mini dump trucks have proven their reliability and economy under steep slope conditions. With technological iteration and large-scale production, this trend will accelerate the replacement process of traditional fuel equipment. KONSTANT is leading the industry towards a greener and smarter future with the core concept of "efficiency, reliability and innovation".

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch

Battery Powered Mini Dumper

Battery Powered Mini Dumper Gasoline Engine Mini Dumper

Gasoline Engine Mini Dumper